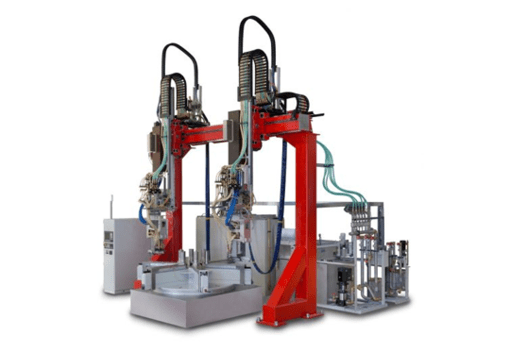

Vertical hardening machines by EMA Indutec can be used universally and flexibly in all common, inductive procedures within a wide range of different applications. Due to its modular construction, the machine guarantees

a customized adaptation to specific requirements such as flow rate, weight of work piece and degree of automation.

Inductive portal hardening plants are ideally suited for industrial drives, wind parks, earth-moving machines, and lifting technology. Our LIBRA portal hardening plants have the following features:

more details

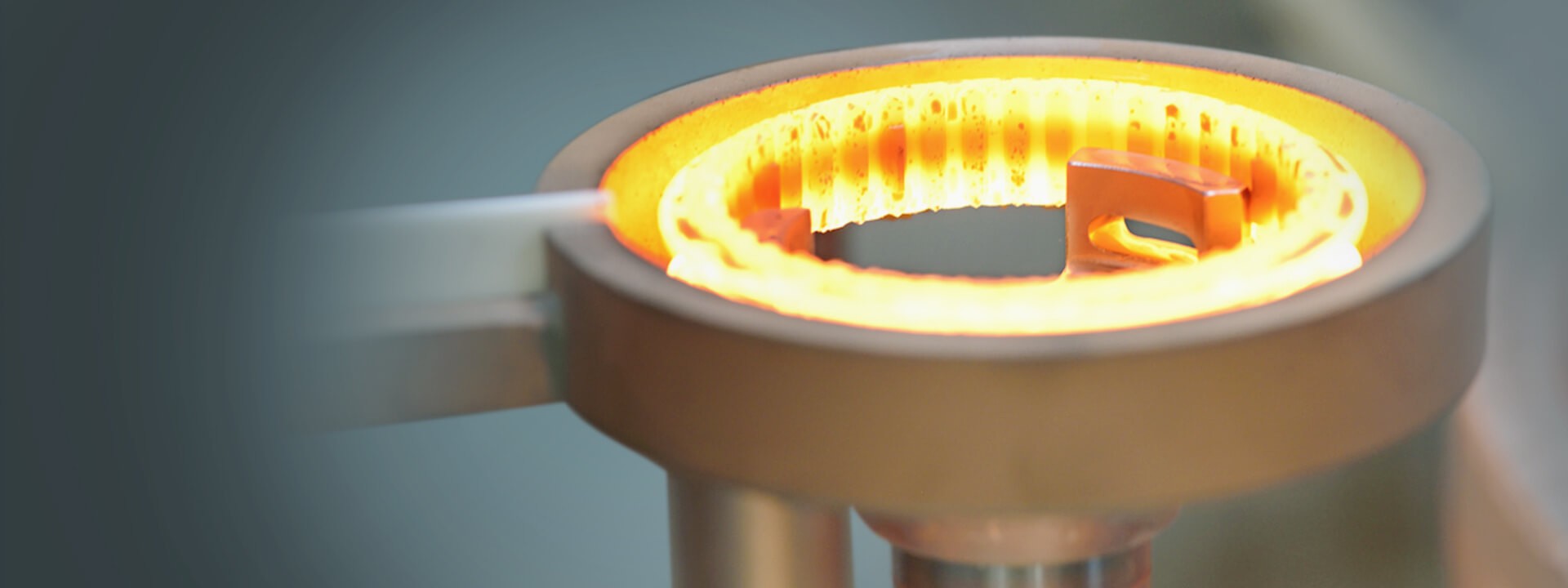

To reduce tedious and costly post-production work on surfaces that have already been hardened, we have worked intensively and successfully over the last few years on calibration hardening in connection with induction-heating and subsequent inductiontempering.

more details

EMA Indutec developed a new inductive hardening and tempering process which combines the benefits of induction heating and hardening with the benefi ts of a press hardening process. Especially automobile manufacturers increasingly require components with higher accuracy for use in sophisticated applications.