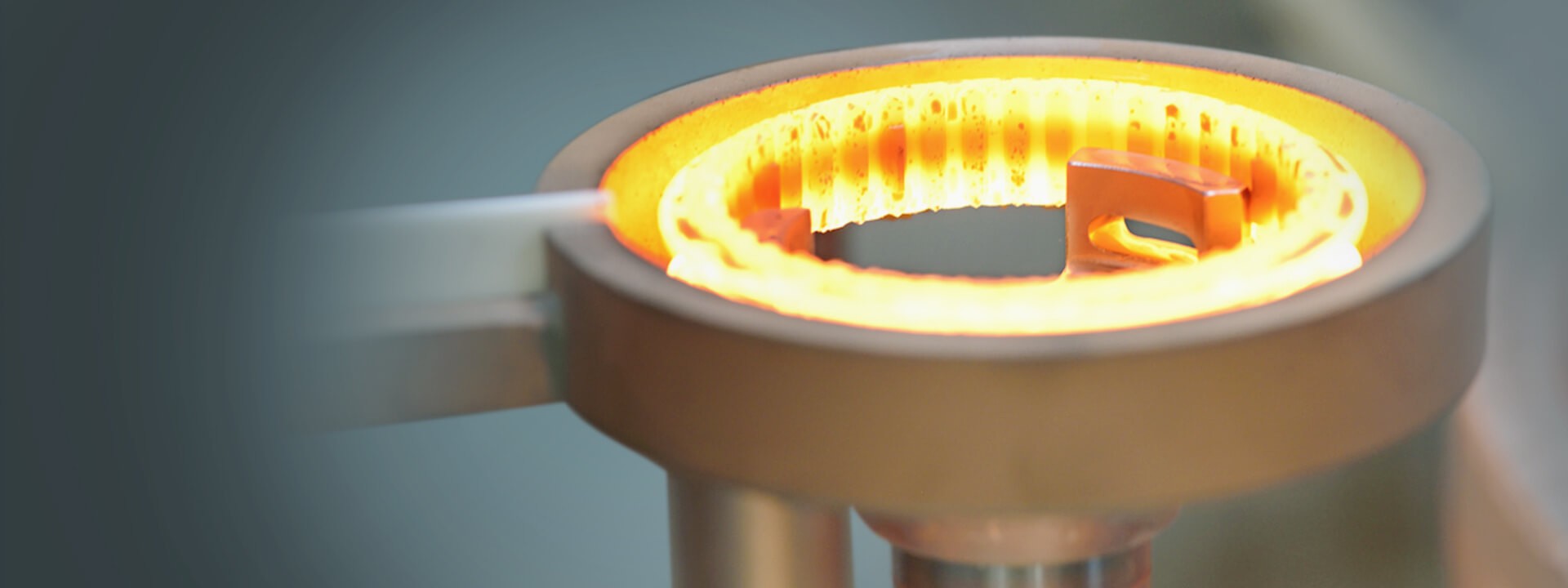

The inductor is the tool of induction heating and always plays a decisive role in the process and the successful use of inductive heating. Due to an alternating magnetic field of the current-carrying inductor, the workpiece is heated in a controlled manner.

Accuracy of the inductors

Since inductors are high-precision tools, they should be checked before by using inspection gauges. Minimal dimensional deviations as well as deviations in the shape and position of the induction tool can have a major influence on heating and the final result.

Inductor cooling

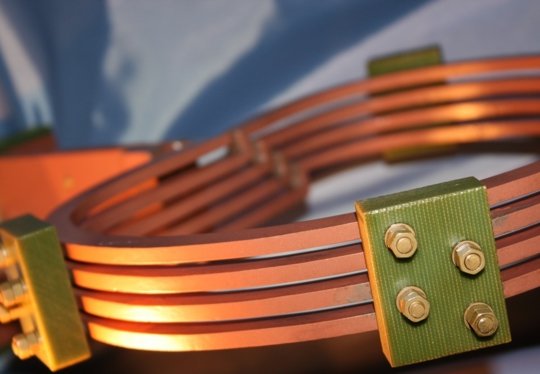

In order to protect the inductor from the radiant heat of the usually very hot workpieces, copper tubes with optimum electrical conductivity are traditionally used for the manufacture of the inductors. This water cooling ensures that the radiant heat absorbed by the inductor is transferred to the cooling water and that the copper of the inductor does not overheat. If cooling is inadequate, the induction tool can overheat and suffer damage.

Professional inductor cleaning and maintenance

For a proper functioning, optimum cooling effect, an exact fit, and for the longevity of an inductor, it is essential that it is cleaned and serviced correctly.Find out what’s especially important, by watching our video tutorial.

Inductor construction

EMA Indutec GmbH as a specialist in the field of induction heating carries out repairs and new constructions according to customer requirements in its own inductor construction department.

Process development

The core competence of EMA Indutec are successful development orders as well as the optimization of complicated processes and an inductor lifetime optimization.

Feel free to contact us with your questions. Our team of inductor experts will be happy to provide you with advice and support!

Inductors from EMA Indutec

(PDF |

4.58 MB |

eng-US )