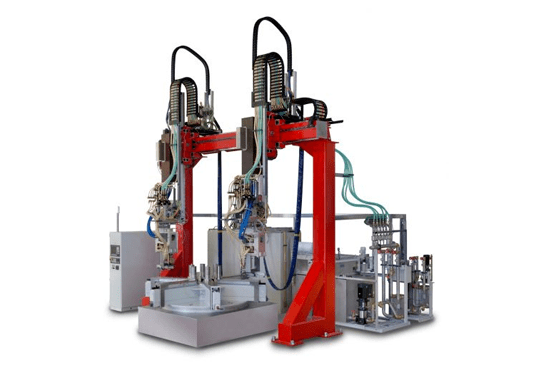

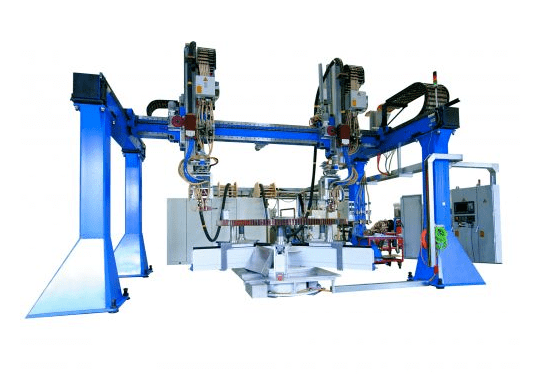

Inductive portal hardening plants are ideally suited for industrial drives, wind parks, earth-moving machines, and lifting technology.

Our LIBRA portal hardening plants have the following features:

Processes

Areas of Application

The modular setup of inductive portal hardening plants allows for a tailored adaptation to customer needs such as flow rate, weight of the workpiece, and degree of automation. This makes for an optimal technical and economical solution for the heat treatment of workpieces, in a consistently high and reproducible quality.

We also offer the option of a web connection as well as an integration of your plant into the existing processes and assembly lines via automation interfaces. Quality assurance packages round off the spectrum of our range of services on offer.

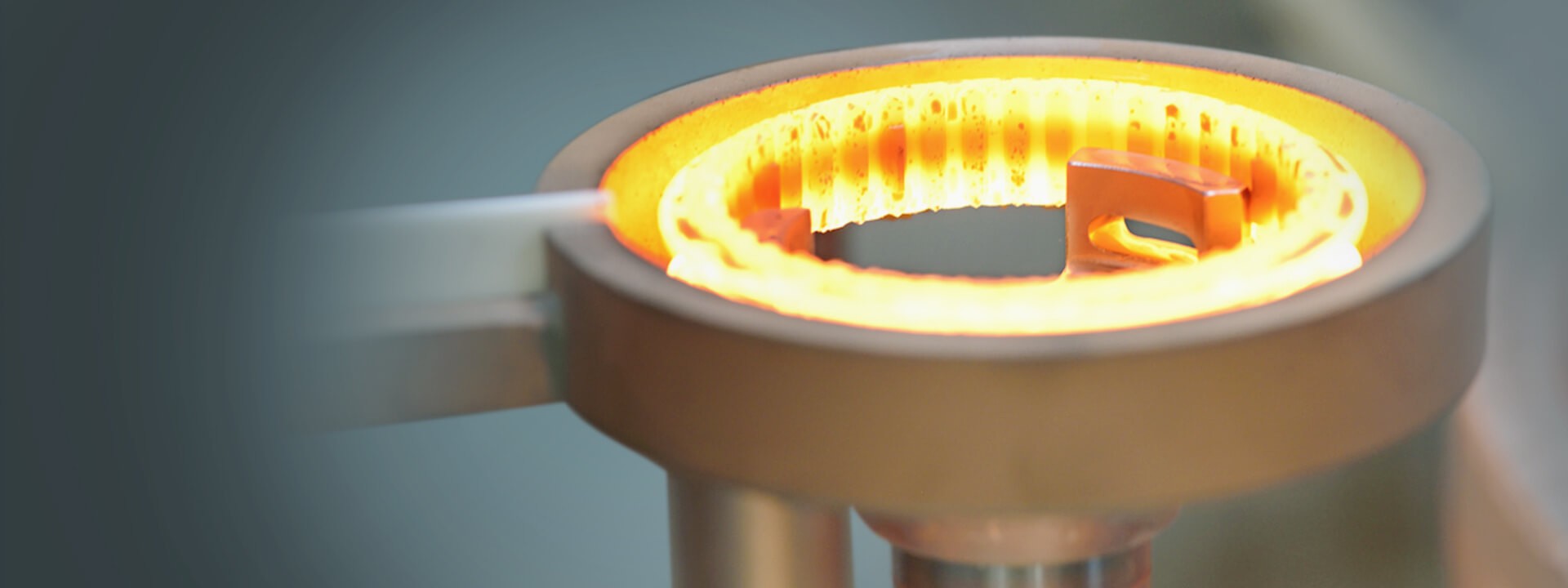

This type of plant is used in the inductive heat treatment of tracks, i.e. rotor blade bearings, which are components of modern wind power stations.

The special features of this plant include:

This video will show you the functioning and benefits of the LIBRA Flip Table portal hardening plant:

More technical specifications can be found in our datasheet containing information on large-diameter bearings and sprocket hardening plants:

Hardening in XXL format - machines of the LIBRA series (PDF | 378.46 KB | eng-US )

Do you have any questions about this system type or are you interested in further details? We would be pleased to provide you with further information.

Hardening in XXL format - machines of the LIBRA series

(PDF |

378.46 KB |

eng-US )